Steel workshops face extreme summer heat – often 10°C+ hotter than outside. Traditional AC is expensive, while roof insulation alone is ineffective. Here are proven ventilation & cooling methods:

1. Natural Ventilation (Lowest Cost)

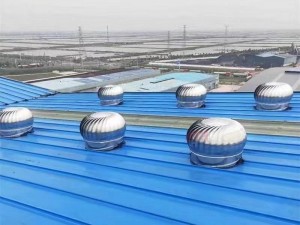

- Roof Turbine Vents:

- Cross Ventilation:

- Install openable windows/roll-up doors on opposite walls

- Creates airflow (wind tunnel effect)

- Tip: Stagger window heights for better stack effect

✅ Pros: Zero energy cost, low maintenance

❌ Cons: Weather-dependent, limited in humid climates

2. Forced Ventilation (Moderate Budget)

- Exhaust Fans (Negative Pressure):

- Wall-mounted fans pull out hot air

- Creates air exchange rate 30-50x/hour

- Use corrosion-resistant models (IP54+)

- Evaporative Coolers:

- Cools air by 4-12°C using water evaporation

- Consumes 80% less power vs. AC

- Ideal for dry climates

✅ Pros: Fast heat removal, improves air quality

❌ Cons: Localized cooling, moderate humidity increase

3. Hybrid Systems (Best Cooling ROI)

- Evaporative Coolers + Exhaust Fans:

- Evaporative Coolers + HVLS Fans:

✅ Pros: 5-15°C temp drop, scalable for large workshops

Key Installation Notes

- Place turbine vents ≤6m apart for full coverage

- Install exhaust fans ≥4m height facing prevailing winds

- Use corrosion-resistant hardware (stainless steel bolts)

- Steel building cooling solutions

- Warehouse ventilation cost

- Industrial exhaust fan system

- Factory heat reduction

- Evaporative cooling ROI

- HVLS fan benefits

- Workshop temperature control

- Low-cost plant cooling

Post time: Aug-08-2025